If your business supplies optical imaging instruments or technologies to the medical, defence or aerospace industries, then you’ll likely have a requirement for optical windows.

Optical windows typically offer protection for sensors and other electronic instruments without any magnifying impact on the light passing through. They can be made from materials such as quartz, UV fused silica, sapphire and optical glass, but a highly popular option continues to be germanium optical windows.

Germanium as an optical material

Germanium was discovered and classified in 1886. However, the existence of a metalloid with the same atomic weight and density had already been predicted long before this date. This prediction bore fruit when a miner working in a silver mine close to Freiberg in Germany stumbled across an ore that wasn’t recognised.

The sample was classified as a new mineral at the local Mining Academy and, upon analysis, was found to be 75% silver, 18% sulphur and 7% a material that had yet to be identified.

Germanium’s properties

Germanium is a heavy, highly brittle substance. It is silver-grey-white in appearance and has a diamond-like, crystalline structure. Using the Knoop hardness testing method, germanium has a hardness of 780, which is almost twice that of Magnesium Fluoride, a material often used for coating optical windows and lenses.

After its discovery, germanium was initially combined with elements such as arsenic and gallium then used in primitive transistors, thanks to its status as a semiconductor. However, since then, its main use has evolved within the optics industry.

There are many properties that make germanium ideally suited for use in optical systems such as lasers, objective lenses for microscopes and wide-angle photographic lenses

One of these important properties is its ability to block both visible and ultraviolet (UV) wavelengths of light but allow the transmission of infrared (IR) light across the 2-14 µm waveband.

This makes it incredibly useful in applications that deal with IR optics, such as thermal imaging and infrared spectroscopes. Other applications that might make use of germanium include the following:

Night vision goggles

Night vision goggles are used in military and defence settings but also in rescue and search operations. For example, searching for an individual lost at sea involves finding a single person floating amid a massive area of cold, dark water – an almost impossible task in daylight, let alone at night.

Germanium is used in the manufacture of night vision lenses used in situations like this and is particularly effective in marine environments because it is impervious to water, salt, alkalis and acids, with the exception of nitric acid.

Heat detection

Germanium optical windows can be used in a range of devices that detect the presence of heat. They’re ideal for this as they offer the ability to measure IR leakage.

Applications for this kind of technology range from sensors used to test and monitor buildings for insulation effectiveness to devices used by firefighters to pinpoint the position of a blaze.

In the latter example, the ability to transmit across the IR spectrum is particularly useful because IR waves are much less likely than visible light waves to scatter off smoke and soot particles.

Security and surveillance

The advantages of IR enabled equipment in the field of security and surveillance are clear – the perimeter surveillance systems that use IR detection function just as effectively under cover of darkness as they do during the day.

Medical and scientific diagnostics

Additional uses for germanium optical windows include diagnostic applications across life and medical sciences.

High index of refraction

The fact that germanium also offers an index of refraction which is higher than most other IR transmitting materials makes it the ideal material for lenses as well as optical windows.

The higher refractive index means that the lenses can be thinner than would otherwise be the case, which is vitally important for minimising weight.

The lighter quality of the lenses is particularly important given that germanium is a highly dense element and would therefore usually increase the weight of an application more than other alternatives.

Germanium becomes opaque at temperatures of 70°C and over, making it unsuitable for high-temperature applications unless cooled.

Germanium window coatings

The high refractive index of germanium means that for some applications, an anti-reflective (AR) coating is needed.

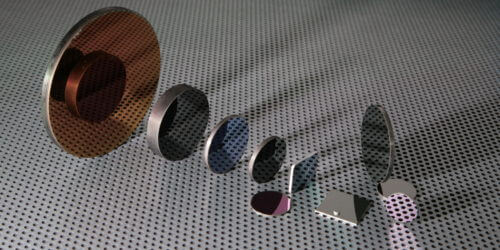

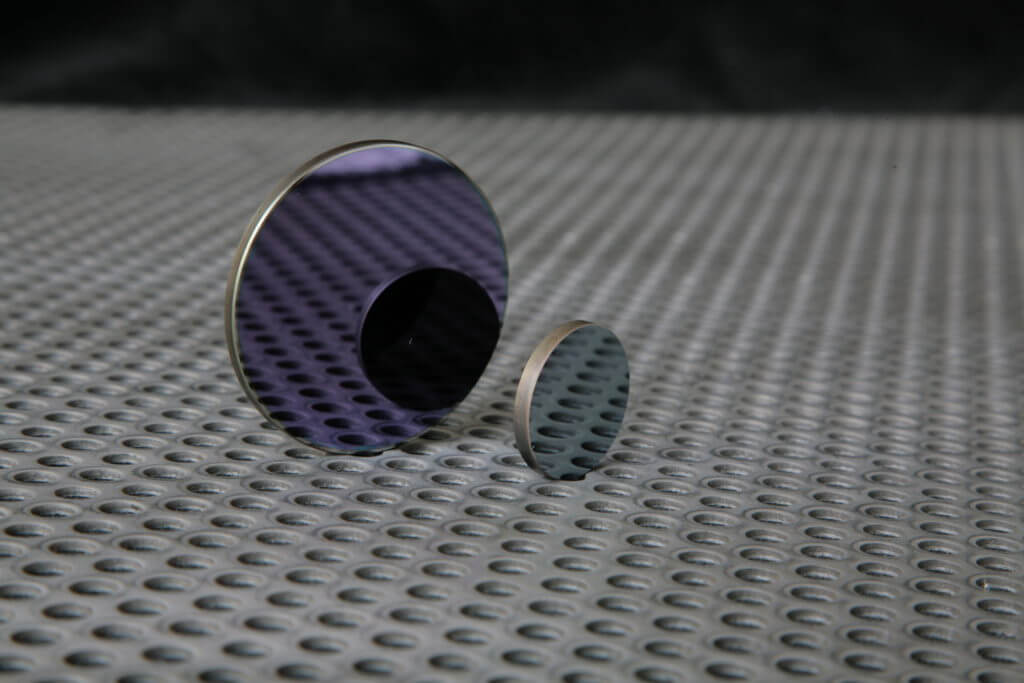

At UQG Optics, we manufacture and supply germanium windows both uncoated and with a range of coatings, depending on requirements.

We can supply windows with an AR coating on one of both sides or with an AR coating on one side and a diamond-like carbon coating on the other.

The extreme hardness of the diamond-like carbon coating means that the window can be used safely in harsh conditions.

Germanium optical windows can be used in a wide varied and range of applications from medicine and military operations to home insulation testing.

Here at UQG Optics, we supply custom and stock Germanium windows in a range of sizes and designs. Our facilities enable us to cut, polish and shape germanium windows with a range of coating options to meet the exact client needs.

Next Steps

If you’d like to find out more about the germanium coated optical windows we supply and how you might be able to make use of them, please contact us on 01223 420329 or email our sales team at info@uqgoptics.com.