What is Fused Silica Glass and Why It Matters in Modern Optics

Fused Silica glass is a high-purity optical material made entirely from pure silicon dioxide (SiO₂). Renowned for its exceptional clarity, thermal stability and resistance to chemicals, it plays a crucial role in some of the most demanding optical, scientific and industrial applications. From deep-UV lithography to high-performance laser systems, fused silica glass provides performance characteristics that far surpass traditional glass materials.

In this guide, we’ll explore the composition, manufacturing processes, key properties, applications and advantages of fused silica glass. Whether you’re sourcing material for UV optics or trying to understand the difference between fused silica and fused quartz, this article delivers everything you need to know.

Understanding Fused Silica Glass: Composition and Manufacturing

What is Fused Silica Made Of?

Fused silica glass is composed of amorphous (non-crystalline) silicon dioxide, or pure SiO₂, which sets it apart from other types of glass. This high-purity composition means it contains virtually no impurities, allowing for exceptional optical transmission across UV, visible and IR spectra.

Fused Silica vs Fused Quartz

While often used interchangeably, fused quartz is typically derived from the melting of naturally occurring quartz crystals, which may introduce trace impurities. Fused silica, on the other hand, is manufactured using synthetic processes that yield a higher purity and consistency, making it ideal for precision optical and photonic applications.

How is Fused Silica Glass Produced?

The production of fused silica involves melting pure silicon dioxide using methods that avoid contamination:

- Flame Hydrolysis: Silicon tetrachloride (SiCl₄) is combusted in an oxygen-rich flame, forming fine SiO₂ particles that fuse into a transparent glass.

- Electric Melting: An electric arc melts synthetic quartz powder in a controlled environment, resulting in high-purity fused silica glass.

For a deeper look at how this compares to other materials, check out our guide to quartz glass.

Key Properties of Fused Silica Glass

Optical Clarity and UV Transparency

Fused silica glass boasts outstanding optical clarity, particularly in the ultraviolet (UV) and vacuum UV ranges. This makes it ideal for applications requiring UV-grade fused silica, such as deep UV lithography and UV spectroscopy.

Compared to standard glass, fused silica allows for:

- Transmission down to 185 nm (for UV applications)

- Minimal fluorescence and absorption

- Superior performance in high-intensity light environments

Thermal and Mechanical Properties

One of the defining traits of fused silica is its extremely low coefficient of thermal expansion (~0.5 ppm/°C). This results in:

- Exceptional thermal shock resistance

- Dimensional stability across temperature fluctuations

- Use in high-temperature environments (up to 1000°C continuous use)

Chemical Resistance and Durability

Fused silica is chemically inert and resists most acids, making it well-suited for aggressive chemical environments such as semiconductor fabs or aerospace applications. Its durability includes:

- Resistance to thermal aging and UV degradation

- Long service life under intense mechanical and environmental stress

Common Applications of Fused Silica Glass

Optical and Scientific Instruments

Fused silica is widely used in:

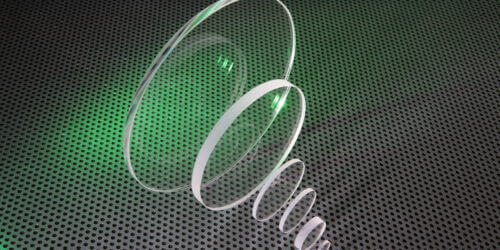

- UV optics, including lenses, prisms, windows and beam splitters

- Spectroscopy equipment

- Astronomical instruments requiring clarity and thermal stability

Semiconductor and Photonics Industries

Due to its unmatched performance, fused silica is integral to:

- Wafer inspection systems

- Photolithography tools (deep UV)

- Laser optics and beam delivery systems

Its low autofluorescence and dimensional stability make it a core material in next-generation chip manufacturing.

Aerospace and Industrial Uses

Engineered to survive extreme conditions, fused silica is used in:

- High temperature viewing windows

- Thermal insulators

- Spacecraft optics and sensors

Its reliability in vacuum, high-radiation and fluctuating temperatures make it indispensable for mission-critical operations.

Why Choose Fused Silica Glass: Key Advantages

When selecting optical materials, fused silica stands out for its balance of performance and durability.

Superior Optical Performance

- High transparency from UV to IR

- No birefringence or inclusions

- Ideal for precision laser systems

Exceptional Thermal and Chemical Resistance

- Withstands rapid temperature changes

- Stable in corrosive environments

Long-Term Durability in Harsh Environments

- UV and thermal degradation resistance

- Excellent aging performance

Frequently Asked Questions About Fused Silica Glass

What is the difference between fused silica and quartz glass?

Fused silica is a synthetic, ultra-pure form of SiO₂, while quartz glass typically refers to melted natural quartz, which may contain impurities.

Can fused silica be used in high-temperature environments?

Yes, it performs reliably up to 1000°C, making it suitable for thermal and industrial applications.

Is fused silica suitable for UV optics?

Absolutely. It offers excellent transmission down to 185 nm, ideal for UV-grade optics.

Ready to Order or Need Expert Guidance?

Contact UQG Optics for expert advice and high-performance fused silica solutions. Our team will help you choose or customise the right component for your specific needs.