In our previous blog post on IR Fused Quartz Windows we explored the fundamental properties and broad applications of this remarkable material. Today, we’re looking into how IR fused quartz is transforming specific fields, particularly gas sensor technology and precision optics.

Key Takeaways

- IR fused quartz is revolutionising gas sensor technology, offering superior accuracy and sensitivity

- In precision optics, IR-fused quartz enables high-performance components for demanding applications

- The low OH content of IR fused quartz is critical for advanced spectroscopy and sensing applications

- Available in various grades, IR fused quartz offers versatility and cost-effectiveness for different needs

- Ongoing research continues to expand the potential applications of IR fused quartz in emerging technologies.

IR Fused Quartz as a Game-Changer in Gas Sensor Technology

Gas sensing has been revolutionised by the introduction of IR fused quartz. Its ability to transmit light in the infrared spectrum (260 nm to 3500 nm) makes it an excellent base material for IR gas sensors. This transmission range allows for the detection of numerous gases, including carbon dioxide, methane and various volatile organic compounds.

The low OH content of IR fused quartz, typically 5 ppm or less, is crucial for gas sensing applications. This ‘water-free’ characteristic minimises interference in specific IR wavelengths, enhancing the sensor’s accuracy and sensitivity. Compared to other materials used in gas sensors, such as certain plastics or lower-grade glass, IR fused quartz offers superior stability and precision.

Moreover, the exceptional optical properties of IR fused quartz make it an ideal substrate for IR optical coatings, significantly boosting the sensor’s performance. These coatings can enhance sensitivity, selectivity, and durability, expanding the range of detectable gases and improving overall sensor reliability.

For instance, in environmental monitoring, IR fused quartz-based sensors can detect minute changes in atmospheric gas compositions, providing valuable data for climate research and pollution control.

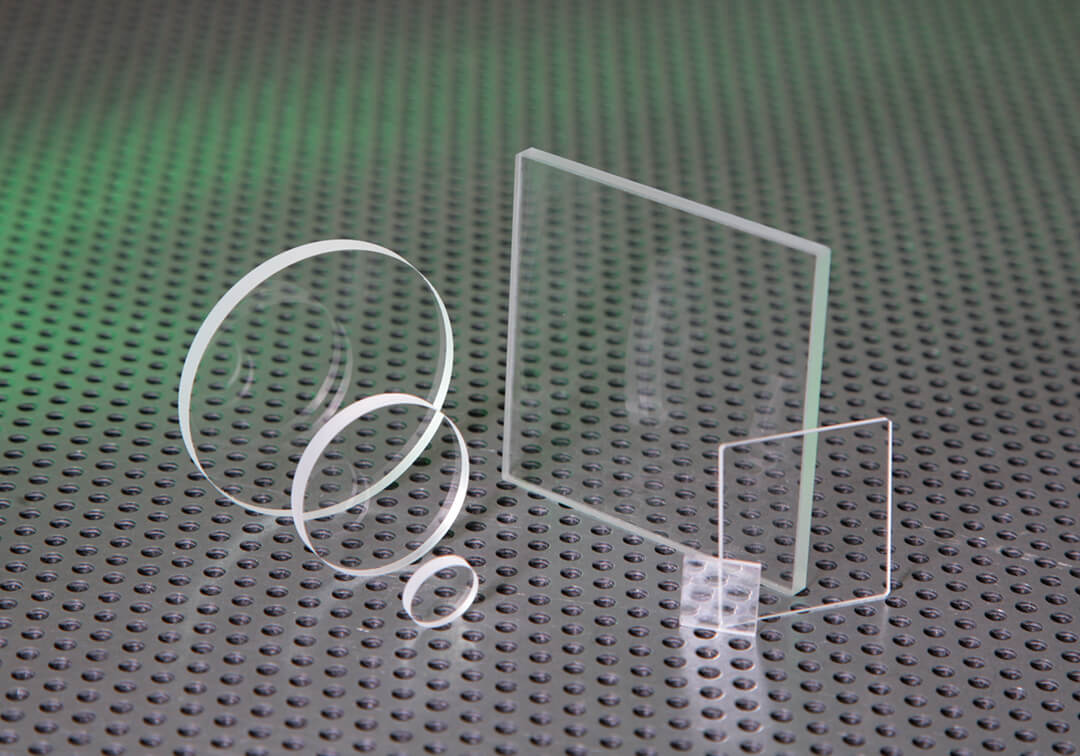

IR fused quartz is also widely used for creating optical filters, such as bandpass, longpass, and shortpass filters, which precisely control the wavelengths of light transmitted. This versatility significantly expands its applications beyond gas sensing to fields like spectroscopy, imaging, and laser technology.

Advancing Precision Optics with IR Fused Quartz

Its use in IR filters and precision camera windows is particularly noteworthy. The material’s exceptional thermal stability, with an extremely low coefficient of thermal expansion, ensures that optical components maintain their shape and properties across a wide temperature range.

This stability is crucial in applications such as satellite imaging systems, where components must withstand extreme temperature fluctuations while maintaining optical precision. The chemical resistance also makes it ideal for use in harsh environments, such as deep-sea exploration cameras.

A prime example of IR fused quartz in precision optics is its use in high-power laser systems. The material’s high damage threshold and transmission properties make it an ideal choice for laser beam delivery and shaping components.

The Critical Role of Low OH Content in Advanced Applications

This ‘water-free’ characteristic is achieved through sophisticated manufacturing processes, resulting in material with OH content as low as 5 ppm or less.

In spectroscopy applications, low OH content is crucial for maintaining clarity in specific IR wavelengths. It reduces absorption peaks associated with water, allowing for more accurate spectral analysis. This property is particularly valuable in fields such as pharmaceutical quality control and material science research.

Achieving ultra-low OH content presents significant manufacturing challenges. Innovations in production techniques, such as advanced purification methods and controlled atmosphere processing, have been key to producing high-grade IR fused quartz suitable for the most demanding applications.

Balancing Cost and Performance: The Versatility of IR Fused Quartz

One of the most compelling aspects of IR fused quartz is its versatility. Available in various grades, from economical options to ultra-high purity variants, it offers solutions for a wide range of applications and budgets.

For instance, while high-end research facilities might opt for the highest grade with ultra-low OH content for cutting-edge experiments, industrial applications might choose a more cost-effective grade that still offers excellent performance for their specific needs.

The material can also be customised in terms of shape, size and coatings. This flexibility allows for the creation of bespoke components, tailored to specific optical systems or experimental setups.

Future Horizons: Emerging Applications and Ongoing Research

As technology advances, new applications for IR fused quartz continue to emerge. In the field of quantum optics, for example, the material’s properties make it a promising candidate for components in quantum communication systems.

Ongoing research is exploring ways to further enhance the properties of IR fused quartz. This includes developing new coating technologies to extend its transmission range and improve its performance in extreme environments.

The potential of IR fused quartz in addressing future challenges in optics and sensing is significant. As we push the boundaries of what’s possible in fields like space exploration, advanced medical imaging and next-generation communication systems, the unique properties of this material will undoubtedly play a crucial role.

Get a Quote Today

Ready to elevate your optical systems with our premium IR fused quartz windows? Don’t hesitate to reach out for a quote tailored to your needs. Our team is standing by to assist you in selecting the perfect IR fused quartz windows for your project.

Contact us today to discuss your requirements and receive a comprehensive quote. Let us help you push the boundaries of what’s possible with cutting-edge IR fused quartz windows.