Technical glasses are used in highly specialised applications in the scientific and pharmaceutical sectors and in optoelectronics in products such as touch screens, display panels, cover glasses, safety windows, instrument windows, coverslips and microscope slides.

In this article we look at several different types of technical glass materials and substrates available for optical applications, windows and plates.

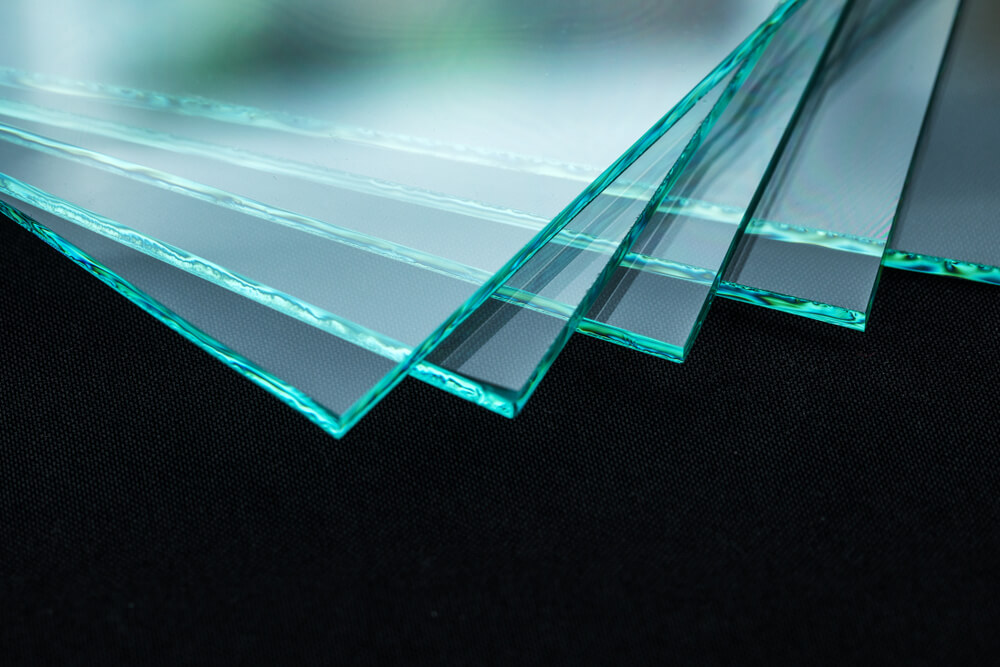

Float Glass

The defining characteristic of float glass (or soda-lime float glass) is that it has a flat surface that can be optically polished for an extremely smooth and distortion-free finish.

In optics, float glass is most widely used in optical window and plates. But as a relatively low cost substrate material, it is also used as the basis for other non-scientific forms of specialised glass such as heat absorbing or laminated glass. Float glass is a highly versatile material which can be produced in transparent or tinted form as is needed for a particular situation.

White Float Glass vs Soda Lime float glass

Soda Lime Float Glass in its natural form has a slight green tinge from its iron content, which means that it isn’t suitable for all applications.

White Float Glass on the other hand as had its iron content removed, making it virtually colourless and offering extremely high light transmission.

The low iron content in the White Float glass also enables it to offer enhanced solar energy transmission. Its optical clarity makes it an ideal choice for optical and photographic systems, while being less expensive than specialist optical glasses such as N-BK7.

Float glass windows and plates are usually supplied as diameters and squares, although can also be produced in custom shapes to a specific requirement.

Schott glass

Specialist glass manufacturers Schott have been developing and supplying high quality optical glass products for more than a century and provide a vast range of specialist glasses for use in industrial, commercial and scientific applications.

There are approximately 120 different glass types in the Schott range and examples include high homogeneity glass which features in astronomy and high-power laser applications and i-Line glass which provides high transmission of UV rays.

Indium Tin Oxide (ITO) glass

ITO glass windows and plates feature an indium tin oxide (ITO) coating enabling enhanced electrical conductivity. The material from which the ITO glass windows and plates are manufactured is usually either Float Glass or Schott Borosilicate.

The process used to coat the glass in ITO will vary depending upon the degree of resistivity required. If below 8 ohms/sq is needed then a hot process is used, whereas if above 8 ohms at room temperature is required a cold coating process is applied.

UQG Optics stock ITO windows and plates in ranges from 4.5 ohms/sq all the way up to 50 ohms/sq.

AR (anti-reflective) coated glass

Anti-reflective (AR) coated glass has had an optical coating applied to either one side or both to eliminate reflections and increase the amount of light transmitted through the glass.

The AR coating used on any specific plate of glass can be designed for the UV, Visible or IR light spectrums, and the coating can be applied to custom optics, acrylic, polycarbonate and heat tempered glass.

AR coated glass of this kind is widely used in optical windows, plates or sheets for medical devices, display panels and LCD modules, and the plates themselves can be supplied with a custom thickness of as little as 0.10mm.

AR visible spectrum coating can be applied to single or both sides of glass, and custom AR coatings are available for the IR spectrum. Standard diameters and squares of AR coated glass are usually available from stock, and custom AR glasses can be produced to the client’s requirements.

Borosilicate

Borosilicate is commonly made Schott Borofloat® 33 but is worth a special mention because of its low coefficient of expansion which gives it excellent resistance to water, acid and saline solutions.

Borosilicate glass properties include:

- Excellent light transmission

- High thermal resistance – it can withstand temperatures over long periods up to 550°C

- Great chemical durability

- Superior mechanical strength.

It is ideal for use in windows and plates, with applications including sight glasses, windows for lighting, heat resistant glass and viewports. As with other materials, it is supplied from stock AR coated sheets of 1.10mm and 2mm thicknesses or made to customer design specifications in any shape or dimension.

Next Steps

Here at UQG Optics we provide a wide range of technical glasses, either from products held in stock or custom manufactured to meet the requirements of a client. Processes such as polishing, grinding, etching and AR coating can be used to provide a specialist finish to the glass, and our technicians work closely with clients to determine exactly what is needed for each specific application.

If you’d like to find out more about the technical glasses we supply, and how you might be able to make use of them, please contact us on 01223 420329 or email our sales team at info@uqgoptics.com