Optical components are at the heart of numerous groundbreaking technologies – from the high-resolution cameras in our smartphones to the cutting-edge medical imaging systems that help diagnose illnesses. While standard, off-the-shelf optics have their place, they often fall short in meeting the specific demands of specialised applications.

We’ll shed light on why custom optical components are an invaluable resource for those involved in original equipment manufacturing (OEM) and research & development (R&D) projects.

Key Takeaways:

- Custom optical components are precision-engineered to meet the specific requirements of a project, offering optimised performance that off-the-shelf components often cannot match.

- The flexibility in design afforded by custom optics enables engineers and designers to solve complex problems and innovate within their fields, from aerospace to medical imaging.

- Scalability is a significant advantage of custom optical components, allowing for cost-effective production from initial R&D stages to mass manufacturing.

- Real-world applications such as satellite imaging, medical diagnostics, and autonomous vehicle technology have benefited immensely from custom optics, enhancing capabilities and pushing technological boundaries.

- Choosing the right supplier for custom optical components is crucial; they should offer expert consultation, rigorous quality assurance, and have a proven track record in optical engineering.

What are Custom Optical Components?

Custom optical components are far more than simple lenses or mirrors. They are precisely engineered components made of glass, crystal, or other optically transparent materials. These components can include a variety of elements, from prisms and filters to aspheric lenses.

Unlike their off-the-shelf counterparts, custom optical components are manufactured to meet exact specifications such as wavelength manipulation, light intensity, size, and other critical dimensions. As such, they offer capabilities that generic components simply cannot match.

Why Choose Custom Optical Components?

- Tailored Performance

Off-the-shelf optical components come with preset specifications. While they can be effective for general applications, they are often not optimised for specialised tasks. With custom optical components, you get a product engineered to provide the specific optical performance you need. Whether it’s a lens designed to focus light in a particular pattern or a filter that allows only a specific wavelength of light to pass through, custom optics offer unparalleled performance optimisation.

- Flexibility in Design

The level of design flexibility afforded by custom optics is invaluable when you’re dealing with unique or complex problems. It enables engineers and designers to move beyond the limitations of standard catalogue items. For example, custom optics can be manufactured to meet stringent requirements for environmental resistance, such as high heat or extreme cold, thereby making them suitable for challenging applications like space telescopes or deep-sea imaging.

- Scalability

The benefit of scalability in custom optical components cannot be overstated. For R&D projects, custom components can be produced in low volumes initially for experimentation and testing. Once the design is refined, it can be scaled up to meet mass production needs. This ensures cost-effectiveness at every stage of the project.

Practical Applications for Custom Optical Components?

The specialised nature of custom optical components allows them to be applied in a multitude of high-tech fields. The following examples demonstrate how these custom solutions serve to meet the unique demands of various industries:

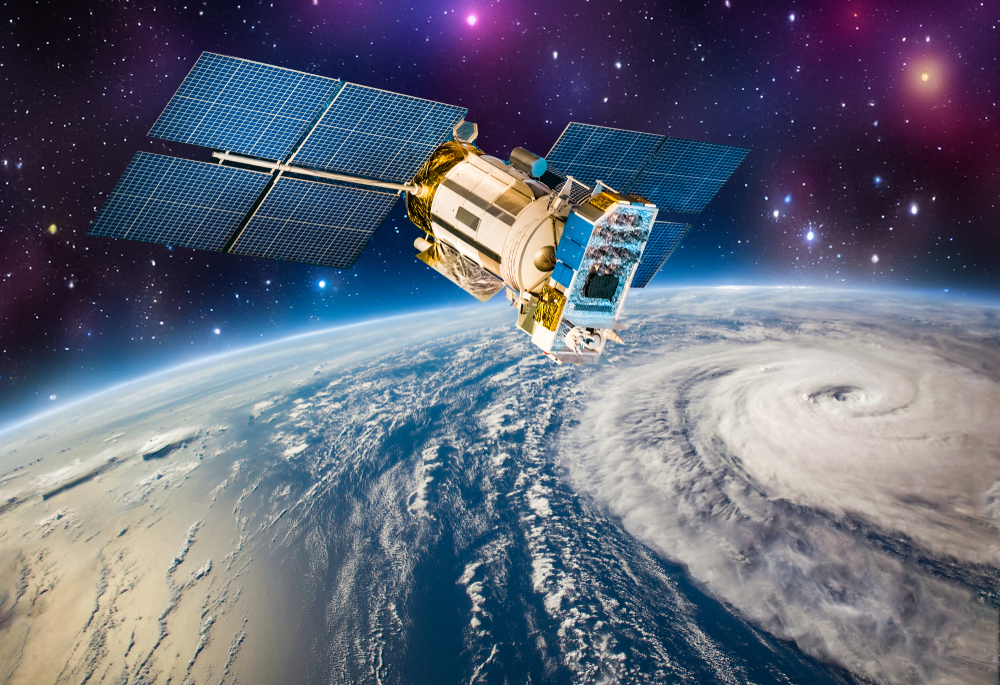

Aerospace and Satellite Imaging

Custom optics have a long history of serving aerospace applications, particularly in satellite imaging systems. Take, for instance, the Hubble Space Telescope, which was equipped with custom-designed mirrors and lenses.

These components were carefully calibrated to capture distant celestial bodies in stunning detail, contributing invaluable data to our understanding of the universe. Additionally, Earth-observation satellites use custom filters to selectively capture specific wavelengths of light, enabling detailed monitoring of environmental factors like vegetation, land use, and ocean health.

Medical Imaging

In medical diagnostics, the need for high-resolution imaging cannot be overstated. Custom optics are key components in specialised imaging devices. For example, optical coherence tomography (OCT), a technology often used in ophthalmology, relies on custom-designed beam splitters and lenses. These components allow the device to capture cross-sectional images of the retina, aiding in the early detection of conditions like macular degeneration.

Similarly, endoscopes equipped with custom lenses and light guides enable doctors to inspect internal body parts with unprecedented clarity, leading to more accurate diagnoses and targeted treatments.

Autonomous Vehicles

The rise of autonomous vehicles has led to a surge in demand for custom optical components. Sensors and cameras in these vehicles often use custom-designed lenses to achieve high-resolution imaging and long-range object detection. For instance, LIDAR systems in self-driving cars employ custom optics to send and receive laser beams, which are then used to create a three-dimensional map of the vehicle’s surroundings. This is vital for real-time decision-making and ensures safer navigation.

Choosing the Right Partner for Custom Optics

When your project depends on optical performance, choosing the right partner becomes a critical factor. A reliable supplier will not only have extensive expertise in optical engineering but also a proven track record. They should be willing to collaborate closely with you from the design phase through to production, offering expert advice and making adjustments as needed to meet your project’s unique demands.

Custom optical components have carved a niche for themselves by offering unparalleled performance, design flexibility, and scalability. They are instrumental in advancing technology across a range of fields—from aerospace and medical imaging to autonomous vehicles. When specialised applications require optical components that exceed the capabilities of standard products, custom solutions are not just an alternative; they are often the only option.

Contact Us for Your Custom Optical Needs

If you’re embarking on a project requiring specialised OEM optics or optical solutions for R&D, make sure to consult with experts in the field. Their knowledge and experience could be the difference between the success and failure of your project.

Contact our team today, or call us on 01223 420 329 or email us on sales@uqgoptics.com