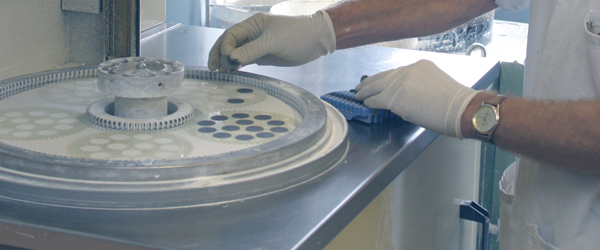

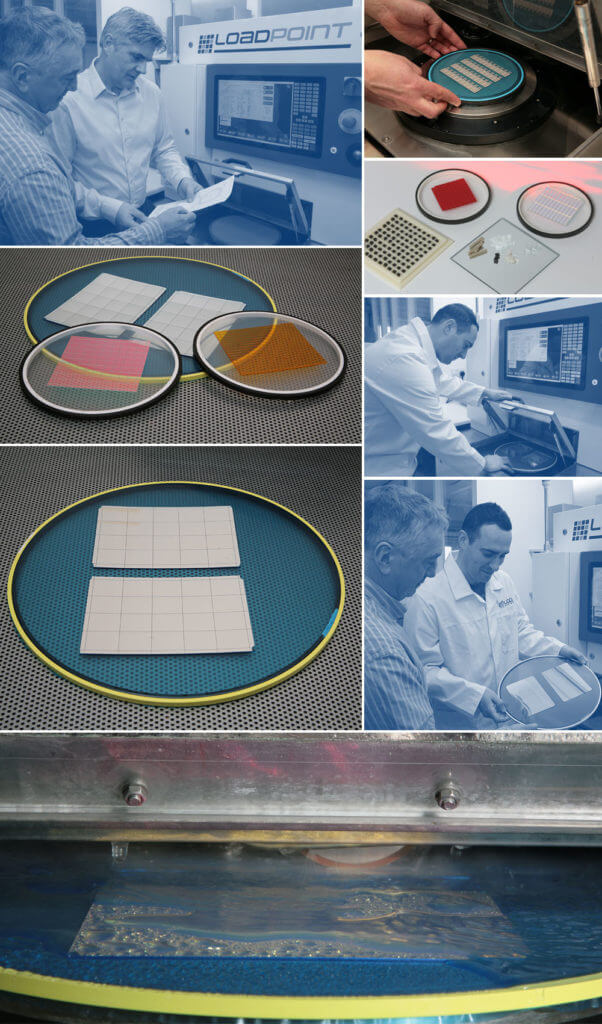

UQG Optics offers precision glass dicing services and for customer-supplied materials, substrates and components. Our cutting technology incorporates vision alignment systems and high-resolution closed loop linear positioning encoders.

We dice to high tolerances and offer an express service to the micro electronics and optical industry. Our equipment includes a Loadpoint NanoAce 3300 and a MicroAce machine. One off R&D jobs are undertaken to volume production.

Dicing Capabilities:

- Saws are fully CNC programmable

- Full cut through, scribed, bevelled and trenching, edges polished

- Thicknesses cut from 100 microns to 6mm

- Dicing tolerance to 10 microns

- Material/component size up to 300mm dia – 200mm square

- Kerf/blade material loss: 100-300 microns

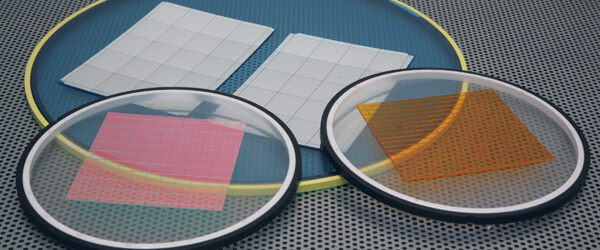

Wafer Dicing and Semiconductor Dicing Services

We specialise in precision wafer dicing and semiconductor dicing services, catering to the intricate needs of the semiconductor industry. Our advanced dicing techniques ensure high precision and minimal kerf loss, essential for the production of microelectronic devices. Utilising state-of-the-art equipment, we can dice wafers of various materials, including silicon, glass, and other semiconductor substrates, with unparalleled accuracy.

Our wafer dicing services are designed to support the manufacturing of semiconductor components, ensuring clean cuts and maintaining the integrity of delicate structures.

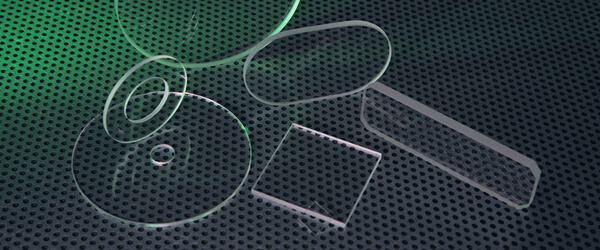

Materials & Components Dicing:

- Coated filters

- Ceramics & alumina

- Fused silica & quartz

- Optical glasses

- Borosilicate

- Sodalime glass

- Sapphire

- Germanium

- Silicon

- Wafers

- Ferrites

- Front surface mirrors

- Glass substrates

- Colour glass filters

- Small diameter rods

Applications Include:

- Nanotechnology

- Biotechnology

- Photonics/optics

- Semiconductor

- Medical

- Sensor

- Optical components

- Electronics

Shipping & Packaging

Waffle packs & trays, Gel packs, On tape & ring, manual sorted and loaded, UV & non UV dicing tape.

UQG optical services are widely used throughout the optical industry. Our state-of-the-art facility offers a wide range of optical engineering services, so contact us today to find out more.